Compression Springs

Monthly MechanismJuliaSpringsIn this #monthlyMechanism we write a simple Julia package to model compressive springs. Springs, of course, are a fundamental machine component and they are well-explained by mechanics. I'm using Fundamentals of Machine Elements as a reference, but many others exist.

The material and shape of a spring completely describe its function, which is summarized by the spring stiffness constant (spring rate) and calculated by

with being the applied force, deflection from the unloaded state, the material's shear modulus, the spring wire diameter, the number of free revolutions of the wire, spring index , and the coil diameter.

In Julia we start with a struct to hold these parameters:

struct CompressionSpring

G::Unitful.Pressure

d::Unitful.Length

D::Unitful.Length

Na::Real

l0::Unitful.Length

endI'm using the Unitful package to add unit handling to the parameters, which means that when instantiated can be given any length, from Ångströms to yards to centimeters

julia> a = 1u"angstrom" + 2u"yd" + 3u"cm"

18588000001//10000000000 mand, given the vastly differing scales, is internally stored as a fraction until needed.

The spring constant can then be calculated:

function springIndex(s::CompressionSpring)

return s.D/s.d

end

function springConstant(s::CompressionSpring)

C = springIndex(s)

return s.G * s.d / ( 8 * C^3 * s.Na * ( 1+1/2/C) )

endThe spring parameters are significantly independent; given the wide variety of wire materials and diameters, and the ability to control coil diameter and number of turns, many spring sizes and constants are available.

As a quick example, here's how to model spring number 184 from WB Jones.

function jones184()

G = 11.5e6u"psi" #zinc-clad "music wire" taken to be ASTM A228 high-carbon steel

d = 0.016u"inch"

D = 0.125u"inch" - d #convert from outer diameter to mean diameter

Na = 11.9 #number of 'active' coils

l0 = 0.75u"inch"

return Springs.CompressionSpring(G, d, D, Na, l0)

endThe jones184() function holds the same information as a datasheet, and whereas datasheets are intended to be read and referred to, jones184() is meant to be used in calculations.

For instance, we can calculate the force at a given displacement,

"""

Calculates the spring force when deflected a distance `l` from the unstretched length.

By convention this force is positive for compression springs and negative for extensional springs in tension.

This function will issue a warning if the spring is compressed more than 85% of its length, where plastic

deformation is likely, or less than 15% where the force may be slightly inaccurate.

"""

function forceAt(s::CompressionSpring, l::Unitful.Length)

f = springConstant(s) .* (s.l0-l) #as per convention, l0-l results in a positive force resisting the compression

# See Shigley1996's definition on pg24.17

if l/s.l0 < 0.15

@warn "Spring likely compressed beyond linear region" s.l0 l f

end

if l/s.l0 > 0.85

@warn "Spring only slightly compressed, calculated force possibly inaccurate" s.l0 l f

end

return f

end

f33 = Springs.forceAt(cs184, 0.33u"inch")

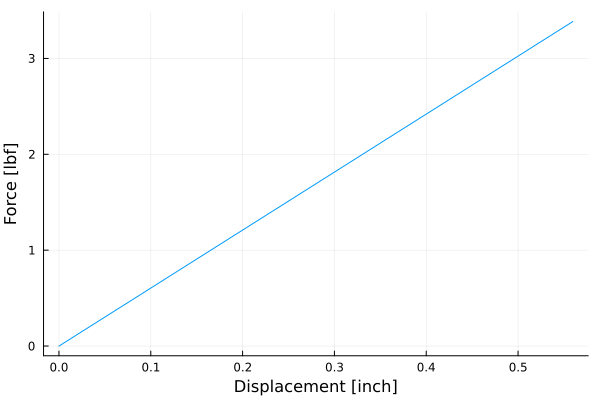

or plot the force/displacement curve,

whose slope is the spring constant .

And that is it for this MonthlyMechanism. I didn't have time to get into spring non-linearities, plastic failure, resonances and surge, or selection criteria...maybe next month. Until then, share on Twitter or LinkedIn, and be sure to subscribe to see next month's mechanism.

— Ben Conrad

- Next: RapidSlide Adjustable Wrench

- Previous: Renishaw Equator